As a manufacturer specializing in stamped metal products, we take pride in delivering components that combine durability, accuracy, and cost-effectiveness. Over the years, our capabilities have grown to support a wide range of industries—from automotive and trucking to office furniture and consumer goods. Each product category reflects our commitment to consistent quality, advanced tooling, and reliable mass-production capacity.

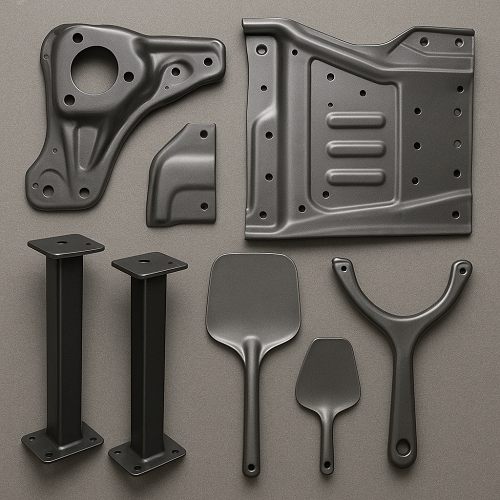

Our automotive stamping division supplies components designed to meet strict engineering and regulatory standards. We manufacture brackets, reinforcement plates, structural supports, and other stamped parts that must maintain excellent dimensional stability under extreme conditions. Working with automotive clients means handling high-volume orders, maintaining tight tolerances, and ensuring every batch meets OEM quality requirements. Our team collaborates closely with engineers during the development stage, optimizing material selection and stamping methods to reduce weight while retaining strength—an essential factor in modern vehicle design.

Automotive OEMs, Tier 1 and Tier 2 suppliers, chassis system manufacturers, vehicle assembly plants, and companies seeking long-term, stable supply partnerships for metal components.

Truck components require even greater robustness, and we tailor our processes accordingly. We produce stamped parts used in suspension systems, cabin structures, utility brackets, and load-bearing assemblies. These parts must withstand long-term mechanical stress, vibration, and harsh environmental exposure. Our tooling is designed to accommodate thicker materials and high-strength steel, ensuring each part performs reliably even under demanding fleet conditions.

Commercial truck manufacturers, trailer builders, heavy-equipment producers, after-market parts distributors, and logistics companies with in-house vehicle maintenance operations.

We also supply stamped metal parts for office furniture, with a focus on table legs and structural supports. These components undergo electrophoretic coating (e-coating)—a finishing method that provides uniform coverage, corrosion resistance, and a clean, modern appearance. E-coating allows us to deliver parts that are ready for assembly without additional processing, reducing both cost and manufacturing time for our customers. Our production line emphasizes surface consistency, smooth edges, and clean weld points to ensure each piece meets aesthetic as well as functional expectations.

Office furniture manufacturers, contract furniture brands, workspace solution providers, table manufacturers, and companies producing modular office systems.

Our pizza shovels showcase the versatility of metal stamping beyond industrial applications. We manufacture both traditional and modern pizza peels using lightweight, heat-resistant materials that withstand continuous kitchen use. Each shovel is stamped for rigidity, smoothness, and comfort, ensuring easy handling in both commercial and home settings. We also offer customization in terms of shape, handle interfaces, and surface finishing to meet branding and functional requirements.

Commercial kitchen equipment distributors, restaurant supply wholesalers, outdoor cooking brands, pizza oven manufacturers, and private-label consumer goods brands.

Our stamped metal slingshots are built with a focus on balance, tension resistance, and ergonomic handling. Stamping allows us to create uniform frames that remain strong yet lightweight. We pay attention to edge smoothing, thickness control, and structural curvature to ensure safe and comfortable use. With optional surface treatments and design variations, our slingshots appeal to both recreational users and outdoor sports brands.

Outdoor sporting goods companies, e-commerce brands, hardware distributors, hunting and camping equipment suppliers, and private-label product developers.

Across all sectors, our goal remains the same: to deliver high-quality stamped metal products with competitive pricing, stable supply capability, and professional technical support. Whether our customers require complex automotive parts, heavy-duty truck components, aesthetically finished furniture parts, or consumer goods, we work collaboratively from design to production to ensure their success.